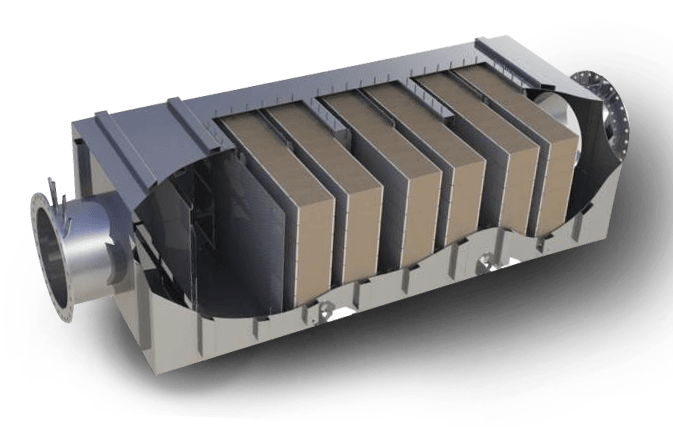

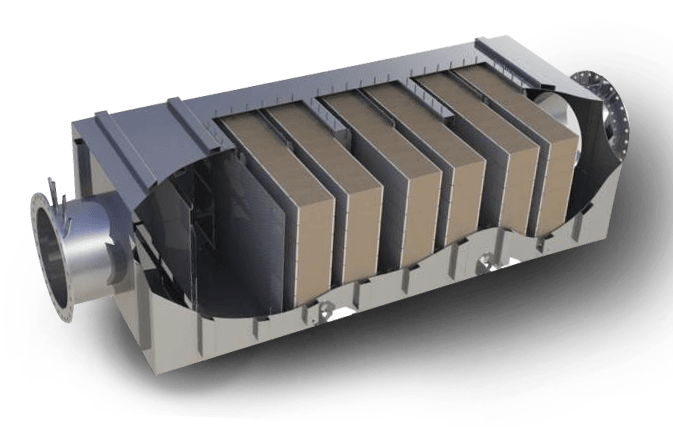

THE SCR PROCESS

The MIRATECH SCR catalyst systems work in two efficient stages – the Oxidation Stage for CO and HC reduction and the SCR stage provides NOx reduction. Both stages work together, drastically reducing harmful emissions to satisfy the strictest regulatory requirements. In the mixing section, either ammonia or aqueous urea is injected into the exhaust stream. Urea is often used instead of ammonia, as urea is less toxic, easier to transport and store, and allows easier permitting. Urea in this system is hydrolyzed and breaks down in the exhaust stream to form ammonia.

The Oxidation Stage uses oxidation catalyst elements, with surface coatings impregnated with precious metals, to reduce CO, HAPs, and VOCs—oxidizing these pollutants to form water and carbon dioxide. Ammonia, whether injected directly or formed from urea, reacts with NOx at the SCR catalyst to form harmless water and nitrogen.

MIRATECH Analysis Controlled Injection System (ACIS™) makes SCR control easier than ever. ACIS, featuring info-at-a-glance graphics integrates key monitoring points and control functions.

The key? ACIS closed-loop system continuously monitors actual post-catalyst NOx emissions and automatically adjusts reactant injection to ensure compliance whether you’re running a base-load or load-following application from idle to 100% rated load.

The payoff? Comfort in knowing that continuous, ongoing compliance and maximum efficiency in reactant use via an incredibly user-friendly monitoring and control system. Plus, with features like remote monitoring and troubleshooting, ACIS cuts man-hours required for SCR operations.

- Applications

- Pollutants

- Power Generation

- Energy Infrastructure

- Rail

- Air Compression

- Liquids Pumping

- Bio-Gas

- Greenhouse CO2 Enrichment

- Industrial Marine

- NOx

- NO2

- CO

- VOC (NMNEHC)

- HAP's