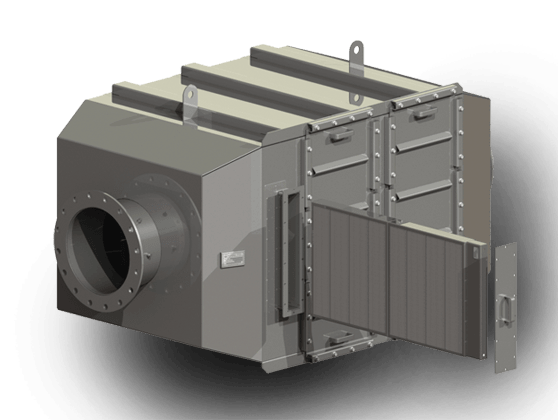

Our passive DPF technology uses porous, wall-flow ceramic filters, shown to be thermally and mechanically durable in engine operation. The filters are assembled in modular arrays within MIRATECH’s LTR and MIRA-CUBE housing lines. These modular DPF filters are stackable, to tailor particulate matter reduction capacity to an engine’s specific needs. MIRATECH’s filter construction also affords much greater particulate trapping and “storage” capacity than other filters. Filter regeneration temperatures and back pressures are low and stay well within OEM limits.

Coated with a sulfur-resistant catalyst to reduce the temperature required for particulate oxidation, MIRATECH’s DPF filters allow PM burn-off or “passive regeneration” using engine exhaust heat at temperatures as low as 500°F/260°C, depending on the engine’s particulate production. Unlike some soot filters, MIRATECH’s design limits NO₂ production, which means no worries over regulated by-products.

- Applications

- Pollutants

- Rail

- Power Generation

- Air Compression

- Liquids Pumping

- Industrial Marine

- CO

- VOC (NMNEHC)

- HAP's

- Particulate Matter (PM)